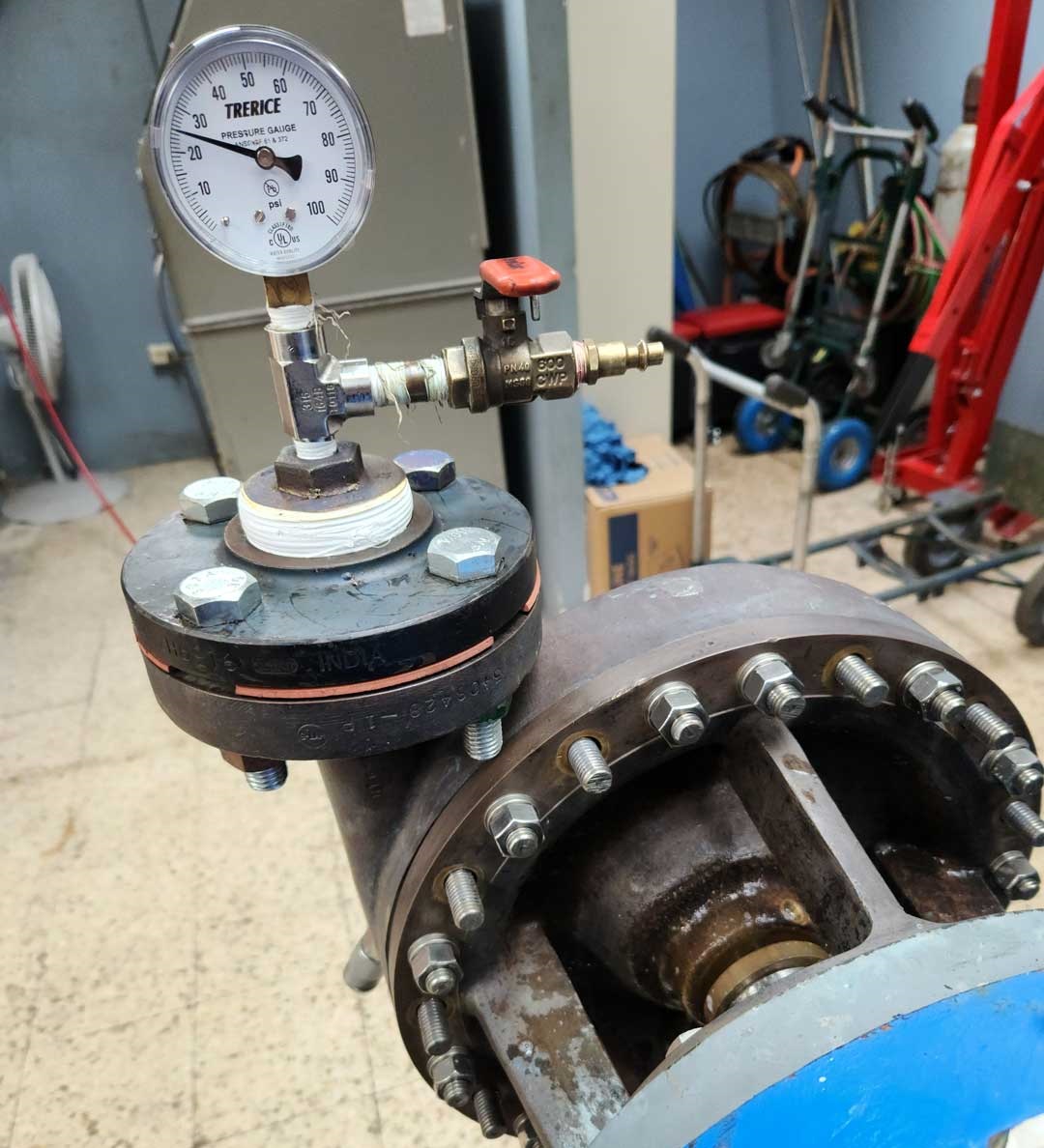

General

PSD Service Department takes great pride in keeping your business running safely and efficiently. Our certitied service facilities are required to maintain strict capacity standards in the areas of repair, service, inventory and physical facility layout. Working closely with our customers, our highly trained engineers and technicians will review your requirements and offer a specific treatment tailored to meet your needs.

- On-site Maintenance Seminars.

- 24 Hour Emergency Repair Service.

- In-house or On-site Pump Repair / Rebuild / Refurbish.

- Virtually All Fluid Handling Equipment Repairs.

- Pump & Equipment Pick-up and Delivery Available.

- Repair of Pumps Gearboxes Mechanical Seals Motors & More.

- Pump Machining & Sandblasting.

- Protective Coatings for Pump Impellers, Diffusers & More.